In a recent webinar delivered by BWF Technical Director Kevin Underwood during BWF Members’ Week, he made the compelling case for the circular economy and how the woodworking industry is positioned to make a positive contribution.

What is the Circular Economy?

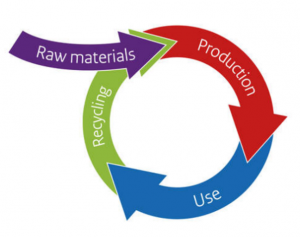

Probably the easiest way to start thinking about the circular economy is to contrast it with how our industrial economy traditionally works. We take materials, make something, use it and then discard it – take, make, waste. That’s a linear system, consuming and depleting resources and creating waste and pollution.

The Circular Economy, in contrast, aims to keep products, components and materials in use for longer, and reuse them, so we get more value (usefulness, or productivity) from them.

It has been proposed as a solution to local and national resource security/scarcity issues and as a way to reduce the environmental impacts of our production and consumption, through methods including designing out waste, disruptive innovation, new leasing models and the use of renewable materials.

Commitment to a more Circular Economy in the UK

The UK is committed to moving towards a more circular economy which will see us keeping resources in use as long as possible, extracting maximum value from them, minimizing waste and promoting resource efficiency. This shift is highlighted in both domestic and international initiatives including The Circular Economy Package (CEP) which introduces a revised legislative framework, identifying steps for the reduction of waste and establishing an ambitious and credible long-term path for waste management and recycling.

The transition to a more circular economy requires changes throughout value chains, including product design, new business and market models, novel ways of turning waste into a resource, and changes to consumer behaviour. The move to a more circular economy will bring the four UK nations environmental, financial and social benefits.

Why is wood the material of choice for the Circular Economy?

Producing timber requires significantly less energy than any other mainstream building materials. For example, producing steel requires many more times the energy needed to produce wood. As a result of its versatility, timber is capable of displacing energy intensive alternatives and reducing pressure on the grid.

Timber is also renewable, it uses low energy processes and generates little waste that can be recycled or used as a source of renewable fuel.

With the amount of wood waste declining since 2009 and the volume of material ending up in landfill much smaller than originally thought, today’s joinery products can be recycled or disposed of in a sustainable manner when they reach the end of their life.

What can you do?

While systemic thinking and collaboration are key to accelerating the transition towards a circular economy, each organisation needs to find what works best for their specific circumstances.

The three key principles of a circular economy – designing out waste and pollution, keeping products and materials in use for longer, and regenerating natural systems, should be embedded in design and manufacturing processes from the very beginning. By rethinking design, material selection and manufacturing processes, your business can capture and optimise the business value of circularity.

The BWF urge all businesses in our industry to look closely at how they can aid the shift towards a circular economy, learn from the success of others, look at case studies, take the information and insight needed and apply it to your business to make a real impact and enjoy the social, economic and environmental rewards.

Further Guidance and Information:

Circular Economy Package Policy Statement – https://www.gov.uk/government/publications/circular-economy-package-policy-statement/circular-economy-package-policy-statement

The Environment Bill – https://www.gov.uk/government/publications/environment-bill-2020

British Standards:

BS EN 15804:2012 + A1:2013:

BS EN 15804 gives guidance around core product category rules relating to Environmental Product Declarations (EPDs) for construction products and services.

This standard provides a structure to ensure that all Environmental Product Declarations (EPDs) of construction products, construction services and construction processes are derived, verified and presented in a harmonized way.

An EPD communicates verifiable, accurate, non-misleading environmental information for products and their applications. It supports scientifically based fair choices and stimulates the potential for market driven continuous environmental improvement.

This European standard helps develop a Type III environmental declaration of construction products and is part of a suite of standards that are intended to assess the sustainability of construction works.

BS EN 17213:2020:

This document provides product category rules (PCR) for Type III environmental declarations for windows and pedestrian doorsets as defined in EN 14351?1 and EN 14351?2. Windows and pedestrian doorsets additionally providing fire resistance and/or smoke control characteristics according to EN 16034 are also covered by this document.

The Routemap to Zero Waste in Construction

Recently the Construction Leadership Council published its routemap to zero avoidable waste in construction. The routemap contains key recommendations for industry and government on how to manage construction waste to increase efficiency, reduce carbon and save cost. Explore the Interactive Routemap here – https://www.constructionleadershipcouncil.co.uk/wp-content/uploads/2021/07/ZAW-Interactive-Routemap-FINAL.pdf