Businesses are refocusing their sustainability agenda through the lens of human and planetary health. This is partly because the business case for healthy buildings is now well understood, partly because buildings are ultimately designed for people (happy people are productive people) and partly due to the wakening realisation that air quality control is as important as climate control. The concept of building physics is now well understood, but building chemistry is new to most actors in the construction industry. In addition, it is highly complex.

Ultimately this subject divides into three areas:

- the health implications of bringing a product to market (focussed on extraction and production

- indoor air quality and how we interact with buildings

- what happens at the end-of-life (either when a product has reached the end of its service life or indeed what happens during a premature end (e.g. in a fire).

We have prepared a brief introduction to these three areas of work, but will be keeping this page refreshed as we develop this important agenda to support woodworking businesses in the UK.

Health: Bringing a Product to Market

Health: Bringing a Product to Market

Health is a critical element of new building standards that recognise that many human beings come into contact or consume, directly or indirectly, many harmful materials and chemicals daily. In addition, countless other forms of plant and animal life are also exposed. Standards such as Cradle2Cradle seek to remove dangerous technical nutrients (synthetic materials such as mutagenic materials, heavy metals and other dangerous chemicals) from current life cycles. If the materials we come into contact with and are exposed to through their production processes on a daily basis are not toxic and do not have long term health effects, then the health of the overall system can be better maintained.

The process of certificating against the standard involves identifying the chemical composition of the materials that make up the product. Particularly hazardous materials (e.g. heavy metals, pigments, halogen compounds etc.) have to be reported whatever the concentration, and other materials reported where they exceed 100 ppm. For wood, the forest source is required. The risk for each material is assessed against criteria and eventually ranked on a scale with ‘A’ (materials of low risk), ‘B’ assessed, those chemicals with moderate risk but acceptable to continue to use, and X or banned for materials such as PVC that are identified within the standard as having high risk and would need to be phased out.

Health: Indoor Air Quality, VOCs and Timber

Health: Indoor Air Quality, VOCs and Timber

The Royal College of Physicians is currently working on a report (to be published later this year) focussing on the health problems associated with Indoor Air Quality, this is likely to have a similar impact as their work on the subject of external air quality (Every Breath We Take, authored by the Royal College of Physicians) which catapulted debate into the mainstream in 2016. This report was quickly picked up by mainstream media and politicians and led to Client Earth challenging the government to publish it’s air quality plan and, despite purdah, winning this challenge. The Education sector is already ahead of the curve on this issue and in June 2017 a revision of BB101 is expected, relating to indoor air quality in new schools by the Educational Funding Agency. The National Institute for Health and Care Excellence (NICE) are also commencing a 2 year work programme on defining standards for indoor air quality. All these activities will lead to the ever-growing focus on healthy products and reducing the risk of exposure to Volatile Organic Compounds (VOCs).

VOCs are a large group of carbon-based compounds (hence use of the term ‘organic’, which is not the same organic used in relation to food or agriculture) which evaporate readily at normal (room) temperatures. They are produced naturally by numerous plants and are responsible for the familiar aromas of fruits and flowers. In fact almost everything which has a smell is releasing VOCs. They are also derived from petroleum.VOCs are widely used in perfumes, medicines, flavouring and aromatherapy. They are the active ingredients of the aroma and flavour of hops. They are also used in paints and varnishes. As well as having no adverse effect on human health, depending on their nature, they can, in varying degrees, be both bad for you and good for you.

The use of VOCs (and chemicals in general) is strictly regulated: in the EU the European Chemicals Agency is ‘the driving force among regulatory authorities in implementing the EU’s ground-breaking chemicals legislation …’ ; REACH, for the Registration, Evaluation, Authorisation and Restriction of Chemicals, is a regulation of the EU adopted to improve the protection of human health and the environment from the risks that can be posed by chemicals …’; in the UK the Health and Safety Executive is responsible for the ‘Control of Substances Hazardous to Health (COSHH) Regulations 2002’ in the workplace.

Every chemical substance has a ‘CAS’ number, a unique identifier assigned by the Chemical Abstracts Service (like a book’s ISBN number). EN 16516 lists three of the above – 3-Carene (498-15-7), α-pinene (80-56-8) and β-pinene (127-91-3) – together with Limonene (138-86-3) and ‘other terpene hydrocarbons’, all of which are available in liquid form and considered in that form, according to EN 16516, as ‘dangerous substances’ and therefore coming with the requirement for testing to determine emissions to indoor air. Limonene is found in abundance in the peel of citrus fruits but, unlike turpentine from wood, it can just be squeezed out of the peel!

It is recognised that concentrations of VOCs are typically 5-10 times higher indoors, than out doors . The business case for greater attention to healthy products and good indoor air quality is now well understood and illustrated below.

Natural VOCs and wood

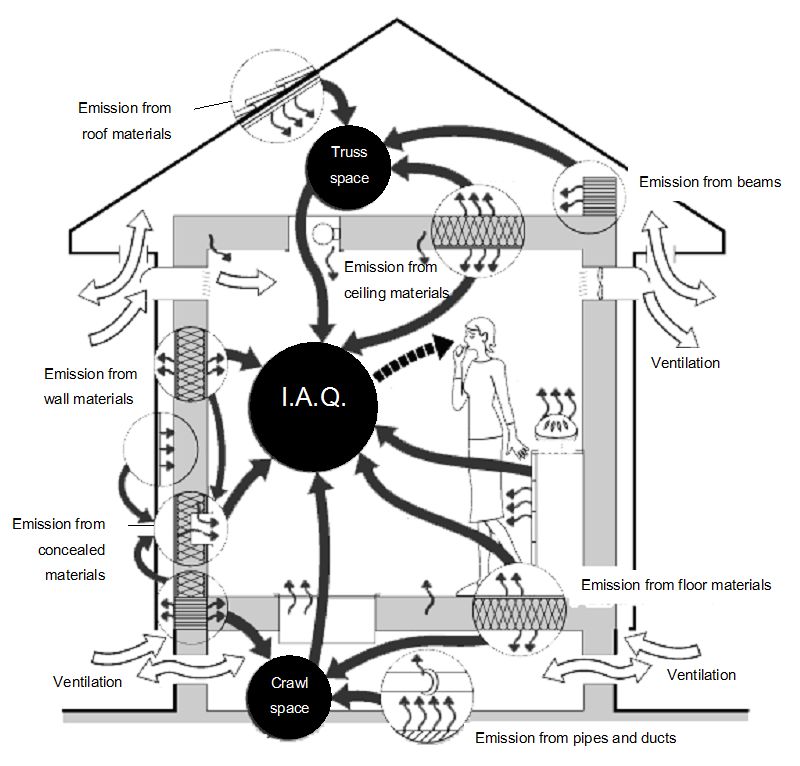

VOCs are numerous, varied, and ubiquitous. They are included in wood products – solid wood, engineered products (OSB, MDF, etc.), flooring products, coatings (paints, finishes, sealants, waxes), adhesives, mastics, cements, roofing materials and insulation. The cumulative effect of emissions from all the different sources needs to be taken into account when considering indoor air quality (see our latest briefing note of Formaldehyde in timber here).

Terpenes

Wood, as a construction material, is covered by all of that legislation and because freshly sawn pine, in particular, has the unmistakable smell of turpentine. Of all the commonly available wood species it is pines, the most ubiquitous softwood genus worldwide with some 126 species names currently recognised, from which is extracted that VOC familiar to artists for generations – turpentine. It can be produced either by distillation of resin obtained by tapping the tree or from destructive distillation of the wood. It can’t just be squeezed out of the wood. Oil of turpentine is used in decongestants; terpin hydrate, a derivative of turpentine, is used to treat acute or chronic bronchitis; pine resin imparts the unique aroma and taste to retsina. (Mineral turpentine / turpentine substitute is obtained from petroleum and is quite different chemically from natural turpentine. But whether obtained from pine trees or petroleum, don’t drink turpentine!).

The ‘active ingredients’ of the characteristic aroma, and taste, are terpenes – the name derived from turpentine – primarily α-pinene and β-pinene (that name origin quite obvious!) together with lesser amounts of careen, camphene, dipentene and terpinolene. Vitamin A is a terpene.

Formaldehyde

Following the EU decision to reclassify Formaldehyde as a type 1B carcinogen from 1 April 2015, CEI BOIS have produced a document which highlights technical details of potential changes to the use of formaldehyde this might mean in the future.

If changes happen, it may restrict sales of products containing formaldehyde and may mean that only products containing low or zero formaldehyde are sellable. You can find more information here.

BWF has prepared a comprehensive briefing note on Formaldehyde available to download here.

Biophilia

There are considerable opportunities for the timber industry, which resonate with the health and well-being agendas. Biophilia and occupants valuing the connection to natural materials is receiving more attention. The BRE have launched their Biophilia Living Lab at Garston, claiming that biophilia can offer ‘…a 15% boost in productivity.’ (BRE.co.uk) ASBP has noted that very few architects currently collect quotes from happy occupants of their buildings. This subject was covered in a presentation to the BWF Interiors Group in January 2017 in a debate led by reknowned architect Oliver Heath (you can see the presentation here).

Health: End-of-Life

Of growing attention is Fire Toxicity and the health implications of products in a fire:

“Although the inhalation of toxic smoke is the biggest killer and the largest cause of injury in fires, it is very much the neglected area of fire science and fire safety engineering. It was concluded that having toxicity data required by the Construction Products Regulation would ensure data was available for engineering calculations. In the absence of toxicity labelling within the Construction Products Regulations, cooperation between competitor organisations, such as fire test laboratories and between fire safety engineering consultancies, would be the best way to secure publicly available data and hence ensure the life safety in the event of a fire”. Annas report on Fire Toxicity; March 2016 Anna A Stec and T Richard Hull, University of Central Lancashire.

Thankfully most of us do not get exposed to smoke in a fire situation, however, toxins do escape into the air and particularly the Fire Brigade may be at higher risk due to repeated exposure. BWF is currently focussing our efforts on investigating timber products in this field, however, when we start to look at the circular ecoonomy there are a number of issues related to end-of-life recovery, reuse and recycling that are moving up the agenda.

BWF are currently looking particularly into challenges and opportunities related to timber in this field, watch this space and our newletter for more details.

Additional Useful Materials Health Information

Interest in the WELL building standard

WELL was developed by integrating scientific and medical research and literature on environmental health, behavioural factors, health outcomes and demographic risk factors that affect health with leading practices in building design and management.

The first WELL Building certified in the UK was Cundall’s One Carter Lane in 2016. WELL Building demands that the VOC rating of all materials must be between negligible and zero, thus ensuring that office fixtures, fittings and fabric do not expel harmful chemical or organic emissions. As Cundall’s Alan Fogarty explains, satisfying this proved to be one of the most challenging elements of the project. “It immediately reduces your range of options in terms of what materials you can choose from. Even discovering the VOC content was a challenge because most manufacturers don’t commonly list it.

It is apparent that Business is refocusing sustainability through the lens of health; both health for people and the planet. Alan Fogarty from Cundalls has spoken about achieving WELL certification for One Carter Lane in at least 15 events so far this year, including the ASBP Expo in February 2017. What is key with WELL, is that you have to undertake and pass indoor air quality monitoring to get certified. Cundall’s suggest that the cost of WELL was £150/per person, which had a payback of one year, based on a 50% reduction in absenteeism (£90k) and saving from reduced churn (£100k).

Tools to support specification of healthy products

As a result of the need for transparent and trusted health data, a number of tools have evolved.

Portico is a building materials evaluation web application service developed by Healthy Building Network that integrates project management functions and growing database of over 2,500 building materials and products evaluated using Pharos Chemical Hazard database and scored based on material health and transparency criteria. It is a proprietary project of Healthy Building Network and was created in partnership with Google.

Baubook contains over 3.500 products with embodied carbon and health and wellbeing data. The database is managed by IBO in Austria.

Additional recommended reading:

Building Materials, Health and Indoor Air Quality: No Breathing Space? Paperback – 29 Sep 2016 by Tom Woolley (Author and speaker at BWF Members Day 2017)

Wood for Good – 15 facts about health and wellbeing in buildings

Healthy Buildings, the role of Products by the Association of Sustainable Building Products

Hattie Hartman provides highlights from ASBP Healthy Products People Planet Conference